Shenzhen Lixiang refrigeration equipment limited company to welcome you

Collection | Site map

PRODUCT

- Industrial ice water unit

- Water cooled screw chiller

- Low temperature refrigerator

- Explosion-proof chiller

- Electroplating refrigerator

- Deep refrigeration unit -35℃~8

- Refrigeration engineering proje

- Concrete water chiller

- One-piece frozen/chiller unit

- Aquatic equipment -35℃~80℃

- The freezer/cold storage

- Air conditioning series

- Cryogenic cooler

- Freeze-thaw Fresh machine

contact us

hotline :0755-29372978

COMPANY ADDRESS: Shenzhen Baoan District City Shiyan Street Shilong Zi Shi Huan Lu Jinma science and Technology Park

PHONE NUMBER:13430426495 18923477282

TEL:0755-29372978

Fax:0755-29372978

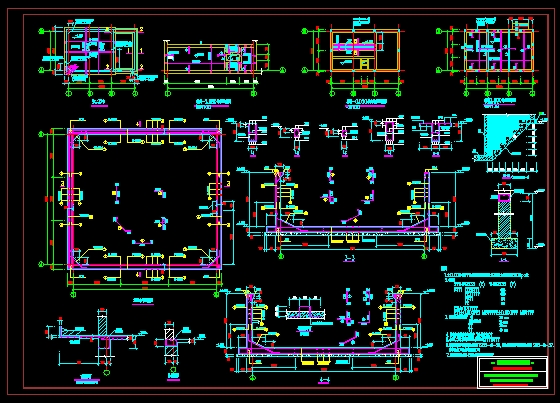

CURRENT LOCATION:HOME > Refrigeration engineering project

Shenzhen City Xiang refrigeration equipment Co., Ltd. based on low-temperature refrigeration equipment in the design and development of all types of, external to undertake all kinds of refrigeration complete sets of engineering general contract; concrete cooling, mixing chilled water system, mine cooling chilled water system, industrial production process cooling water and chilled water system set, industrial cooling water system, frozen food refrigeration system complete, aquatic products frozen system, air conditioning technology regulating system complete and laboratory project simulated environment for all kinds of complete sets of engineering project design, construction, installation and commissioning and maintenance to provide one-stop service.

Our company long-term and all kinds of chemical industry, pharmaceutical industry, mining, food and other industries supporting all types of refrigeration equipment, in industrial refrigeration engineering design and construction has a rich practical experience, for customers to provide refrigeration equipment production manufacturing, engineering system planning and design, construction and installation of, maintenance, integration of refrigeration technology solutions - temperature in the range of + 30 DEG to 80 DEG C for all kinds of industrial refrigeration system solutions.

Industrial process cooling and chilled water system project:

Can provide customers with +30 C ~ -80 technology, cooling, frozen complete solution; such as:

* -3 C - +2 C concrete mixing chilled water, 5 C -7 C concrete pouring cooling water system

* 7 degree -30 C high temperature process cooling water; or high temperature water temperature cooling treatment process;

Room temperature cooling water and large temperature difference cooling treatment process of 0 -10;

--0 low temperature process cooling system of -35 c c c c c c c c c c c c c c c c c c c c;

* -80 ~ -35 C ~ ~ ultra low temperature process refrigeration system; pharmaceutical chemical process cold source

* ice water mixing process cooling system, which is suitable for the process of liquid milk, such as the cooling of the liquid milk, the rapid cooling of food technology, the large load of concrete mixing and cooling.

Two, industrial gas cooling (condensation) and recovery of complete works:

* all kinds of industrial production of steam cooling, liquefaction, recycling and other projects, suitable for natural gas cooling, ammonia cooling and other industrial production of toxic and other cooling, liquefaction recycling process;

Complete system engineering for cooling, condensation and separation and recovery of raw materials in pharmaceutical and chemical industry;

* minimum temperature can be at -80 degrees C, including various types of refrigeration host, gas heat exchanger design and engineering design and construction

Three, frozen, frozen complete works

All kinds of large, medium and small cold storage project; temperature range of +15 to -70 DEG c;

Tuna super low temperature cold storage engineering, temperature -45 to -60 DEG c;

The liquid contact freezer and flat shelf frozen sets of projects (temperature of -40 to -70 DEG C);

Four, mine cooling, dust removal project

* is the major heat source in mine, tunnel heat release of wall rock, coal conveying exothermic, wind down (or up) flow compression heat, generated in the operation of electrical and mechanical equipment of heat, oxidation on heat and other heat sources. Because of the depth of the mining, the -925M level of the ambient temperature is more than 37 degrees Celsius, in the two heat damage zone. In which the whole system important by ground refrigeration system, water system and the underground lose loose cold cold system, the actual underground transport loose cold cooling system is an open system, namely to flow back to the ice melting pool, mining area of the dustproof water due to a small amount of water, from cold water pipe for connecting with working face dust and spray cooling, so as to effectively reduce the downhole environment temperature, improve the production efficiency. Ensure the safety operation.

A refrigerating station is established at the ground near the wellhead, and a low temperature refrigerant carrier with -5 C + 1 C is produced by a refrigerating unit or other pre cooling device. Through the heat exchanger and water heat exchange, the water cooled to 2 - 0.5 Deg. C through the pipeline to mine. The freezing water is sprayed directly on the working area through the nozzle

The low temperature water of *:2 C + 1 C is transported to the pipeline installed in the mining face machine lane by the cold water pump, and the chilled water is sprayed directly on the working area through the nozzle to realize the cooling of the coal mine underground. Not only has the cooling and dust removal function, the traditional mine cooling can not be used, the process of low cost, good cooling effect, not pollute the environment.

Our company long-term and all kinds of chemical industry, pharmaceutical industry, mining, food and other industries supporting all types of refrigeration equipment, in industrial refrigeration engineering design and construction has a rich practical experience, for customers to provide refrigeration equipment production manufacturing, engineering system planning and design, construction and installation of, maintenance, integration of refrigeration technology solutions - temperature in the range of + 30 DEG to 80 DEG C for all kinds of industrial refrigeration system solutions.

Industrial process cooling and chilled water system project:

Can provide customers with +30 C ~ -80 technology, cooling, frozen complete solution; such as:

* -3 C - +2 C concrete mixing chilled water, 5 C -7 C concrete pouring cooling water system

* 7 degree -30 C high temperature process cooling water; or high temperature water temperature cooling treatment process;

Room temperature cooling water and large temperature difference cooling treatment process of 0 -10;

--0 low temperature process cooling system of -35 c c c c c c c c c c c c c c c c c c c c;

* -80 ~ -35 C ~ ~ ultra low temperature process refrigeration system; pharmaceutical chemical process cold source

* ice water mixing process cooling system, which is suitable for the process of liquid milk, such as the cooling of the liquid milk, the rapid cooling of food technology, the large load of concrete mixing and cooling.

Two, industrial gas cooling (condensation) and recovery of complete works:

* all kinds of industrial production of steam cooling, liquefaction, recycling and other projects, suitable for natural gas cooling, ammonia cooling and other industrial production of toxic and other cooling, liquefaction recycling process;

Complete system engineering for cooling, condensation and separation and recovery of raw materials in pharmaceutical and chemical industry;

* minimum temperature can be at -80 degrees C, including various types of refrigeration host, gas heat exchanger design and engineering design and construction

Three, frozen, frozen complete works

All kinds of large, medium and small cold storage project; temperature range of +15 to -70 DEG c;

Tuna super low temperature cold storage engineering, temperature -45 to -60 DEG c;

The liquid contact freezer and flat shelf frozen sets of projects (temperature of -40 to -70 DEG C);

Four, mine cooling, dust removal project

* is the major heat source in mine, tunnel heat release of wall rock, coal conveying exothermic, wind down (or up) flow compression heat, generated in the operation of electrical and mechanical equipment of heat, oxidation on heat and other heat sources. Because of the depth of the mining, the -925M level of the ambient temperature is more than 37 degrees Celsius, in the two heat damage zone. In which the whole system important by ground refrigeration system, water system and the underground lose loose cold cold system, the actual underground transport loose cold cooling system is an open system, namely to flow back to the ice melting pool, mining area of the dustproof water due to a small amount of water, from cold water pipe for connecting with working face dust and spray cooling, so as to effectively reduce the downhole environment temperature, improve the production efficiency. Ensure the safety operation.

A refrigerating station is established at the ground near the wellhead, and a low temperature refrigerant carrier with -5 C + 1 C is produced by a refrigerating unit or other pre cooling device. Through the heat exchanger and water heat exchange, the water cooled to 2 - 0.5 Deg. C through the pipeline to mine. The freezing water is sprayed directly on the working area through the nozzle

The low temperature water of *:2 C + 1 C is transported to the pipeline installed in the mining face machine lane by the cold water pump, and the chilled water is sprayed directly on the working area through the nozzle to realize the cooling of the coal mine underground. Not only has the cooling and dust removal function, the traditional mine cooling can not be used, the process of low cost, good cooling effect, not pollute the environment.

Mr. Deng

Mr. Deng